The second year of my building process began with a three-month break from the project due to work and other things. But in April, I finally had some free time to move on. The electronics in my test rig have been working (not perfect but okay), so I thought it was time to modify the housing, especially the front.

Contents

- Main shell before the front modifications

- New acrylic laser-cut for the front

- Making the cutout in the shell

- Recessed front panel with rounded edges

- Gluing in the acrylic font panel

- Adding supports for the NeoPixel stick

- Adding partitions to reduce light bleed

- First coats of black spray paint

- Spray painting the new greebles

Main shell before the front modifications

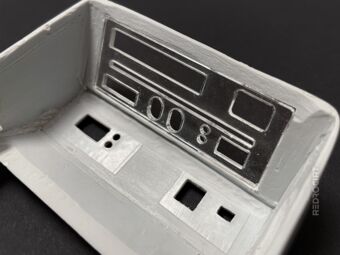

Section titled Main shell before the front modificationsFirst, a few views of the shell with the adjustments made earlier:

- Height of the lower frame increased with 3 mm ABS profiles

- Hole for the USB socket added at the lower end below the hinges

- I had temporarily removed the black USB housing to avoid fitting problems with the ABS profiles

New acrylic laser-cut for the front

Section titled New acrylic laser-cut for the frontBack in October I had decided to use two DotStar Matrix panels for the front LEDs. I had redraw the shape for the acrylic front panel so that the cutouts and holes fit perfectly on the SMD LED positions of the DotStar matrix boards. I decided to use the full width of the LED matrix, which means the new laser-cut acrylic piece is slightly larger than the front cutouts already in the shell.

Making the cutout in the shell

Section titled Making the cutout in the shellI used a high speed cutter to make the main cutout. This took some time, but worked well. Then I carefully filed the hole larger and the edges straight so that the acrylic faceplate would fit inside.

After cutting and filing, this is what it looked like with the acrylic front panel temporarily inserted:

Recessed front panel with rounded edges

Section titled Recessed front panel with rounded edgesOf course, I didn't want to have a flat surface on the front. The scanner panel should be recessed and the edges should be rounded. I carefully filed by hand and sanded again. The corners were particularly tricky.

Gluing in the acrylic font panel

Section titled Gluing in the acrylic font panelTo permanently attach the acrylic front panel, I used a strong dual-component epoxy adhesive (almost transparent, slightly yellowish). While the glue gradually set over the first two hours, I kept checking the alignment and position of the acrylic panel and corrected it carefully if necessary.

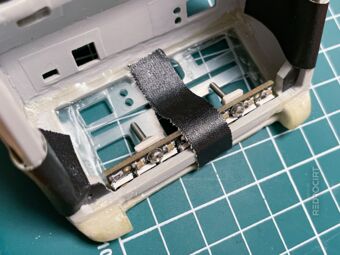

Adding supports for the NeoPixel stick

Section titled Adding supports for the NeoPixel stickWhen the glue was completely dry the next day, I glued in two supports made of white ABS profiles for the NeoPixel stick. I had previously drilled holes for screws in these profiles, adjusted the length and glued nuts on one side. I didn't want to permanently glue down the NeoPixel stick even at this stage, so I carefully removed the screws and the stick after 1-2 hours. I let the glue for the supports dry overnight again.

This is what it looked like the next day, with and without the NeoPixel stick and the lower frame:

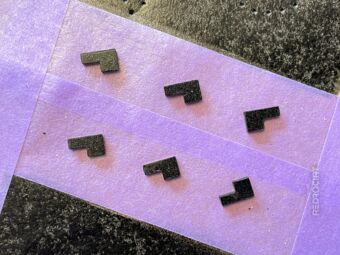

Adding partitions to reduce light bleed

Section titled Adding partitions to reduce light bleedSome other replicas I have seen suffer from light bleeding (stray light from one LED that gives the impression that other LEDs are also glowing). I wanted to try to prevent the light bleeding as much as I could. Therefore, I cut small ABS stripes and glued them to the back of the acrylic panel.

Hopefully, after spray paint is applied, this will reduce light bleed when the LED matrix is placed directly on these dividers. And I also hope that the glue, ABS profiles and spray paint added later will not melt from the heat of the DotStar LEDs (the tightly packed matrix boards can get very hot).

First coats of black spray paint

Section titled First coats of black spray paintAgain, I let the glue for the partitions/dividers dry thoroughly overnight. The next day I cleaned the shell with the new acrylic front, taped off everything but the front, and after adding a plastic primer I applied a first coat of black spray paint. After a few hours, I applied another coat of black spray paint. As a result, I ended up with an opaque layer of black paint on the inside that would further reduce light bleeding.

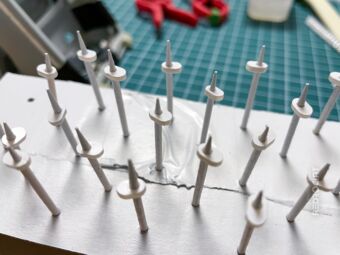

Spray painting the new greebles

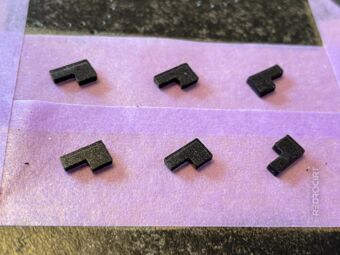

Section titled Spray painting the new greeblesWhile the glue and later the paint on the main case was drying, I also spray painted some of the greebles for the cutouts on the new acrylic front...