New parts for the front scanner array

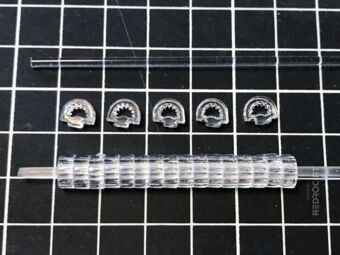

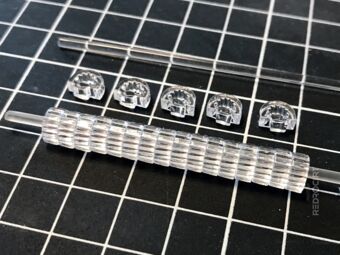

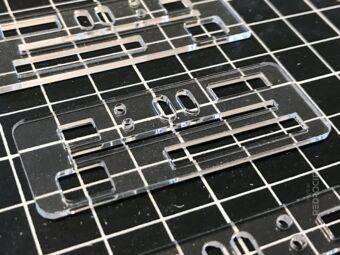

Section titled New parts for the front scanner arrayAfter my failed gluing attempts, I had redesigned the shapes and ordered new acrylic laser cuts for the bottom scanner array. I had made different shapes for the inside, like rings, arcs, stars, and so on. I had also changed the outer contour to better fit on the frame of the kit.

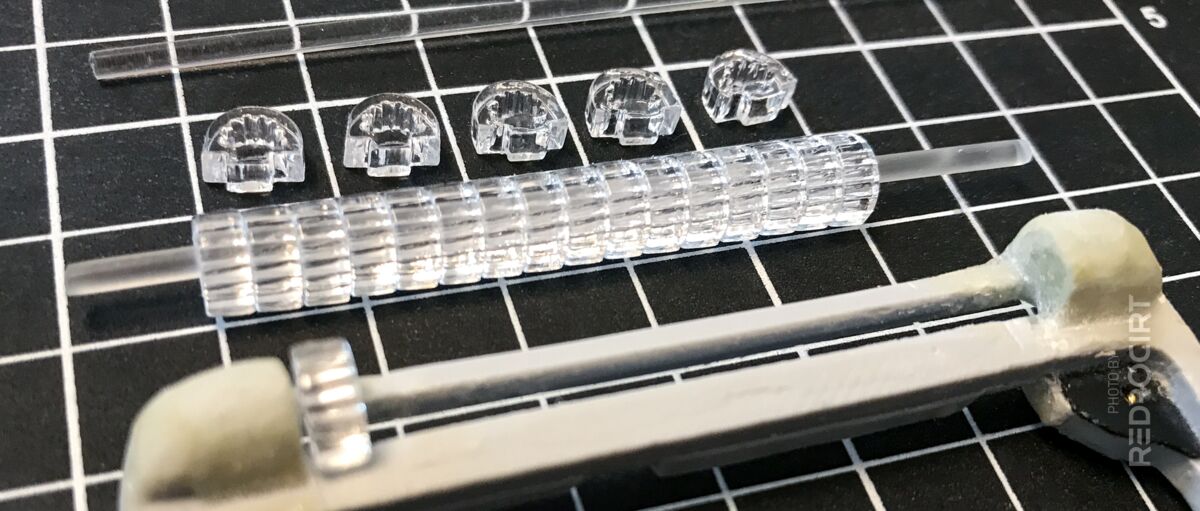

I sorted out the U-shaped arcs (they would have had to be glued again) and some parts that didn't looked good because they were too thin/small for the laser cut. The light refraction on some pieces with the star shape on the inside look great. I sanded down a round acrylic rod to reduce the diameter to fit the holes. Then I put the individual parts on the rod. All elements are evenly aligned without any glue.

I'm happy with the result, and I like the look of these parts with the refracting light. Due to the star-shaped cutouts, the individual LEDs behind it will no longer be recognizable, the LED light will get reflected in multiple directions and the colored LED light will be visible from different angles.

Adjusting the scanner cutout width and ends

Section titled Adjusting the scanner cutout width and endsI wanted my scanner array to be slightly wider than the greeble included in the kit. I carefully filed down the inner sides of the round scanner array ends on the frame to enlarge the opening for the acrylic parts. Then I applied a layer of 2-component glue, let it dry overnight, and repeated this step several times to get a thick layer of glue. Finally, I shaped the ends to my needs by carefully filing and sanding off the glue layer. I wasn't done with it when I took the photos, so the ends look a little odd in the photos.

Imitate flat rectangle LEDs with acrylic greebles?

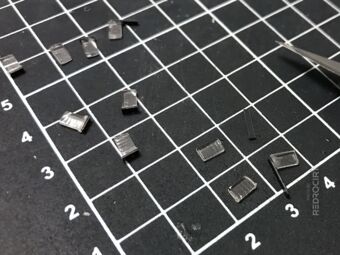

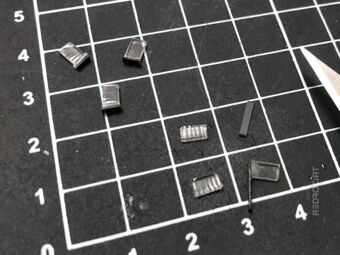

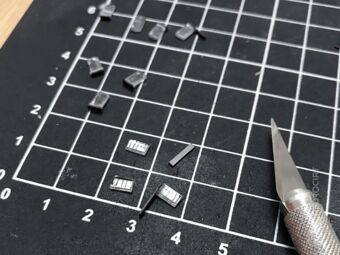

Section titled Imitate flat rectangle LEDs with acrylic greebles?The TR-590 has another flat scanner bar in the center of the front panel, usually with green LEDs flashing from center outwards. I'm not sure yet how to integrate the LEDs for the front panel. But since there is only little space available, I will pretty much have to use tiny SMD LEDs.

To mimic the look of rectangular LEDs, I had ordered thin acrylic rectangles. I thought that maybe I could prevent light bleed in this row by gluing 0.5mm thick opaque PVS between the parts. I'm still testing this, but I hate using glue on these acrylic parts, so I'll probably look for another solution...

Spray painting the white scanner “eyes”

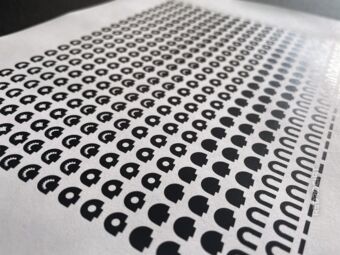

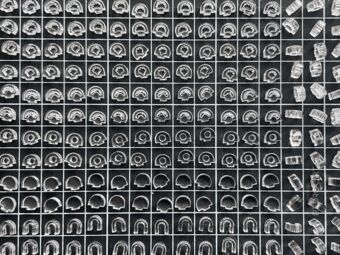

Section titled Spray painting the white scanner “eyes”In the next days I prepared the white scanner elements (looking like cartoon eyes). I had ordered a bunch of them in different sizes (with different outside and inside diameters) because I wasn't sure which size would fit best after painting. For my first spray test, I attached the parts to a wide strip of tape.

I noticed some paint peeling off the corners when I removed the pieces from the tape. Since the parts all had small holes, I changed my approach and put the parts on toothpicks for painting. After the first coat dried, I flipped all the pieces over and applied another coat of paint on the other side.

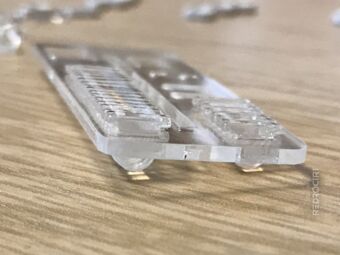

Front scanner greebles fitting test

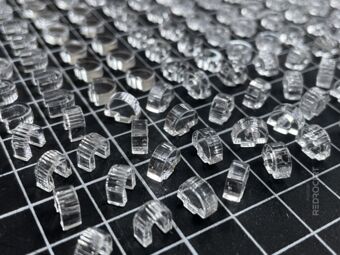

Section titled Front scanner greebles fitting testThe TR-590 has two rows of protruding round scanner arrays on the front. I had ordered 2mm thick laser cut acyl pieces with tiny legs and various lengths. Some of them fit perfectly into the cutouts of the front panel (which was also ordered as a custom laser cut).

I'm not going to permanently attach them to the front panel yet, as I'm not sure how I'm going to make the LEDs for the front scanner panel.